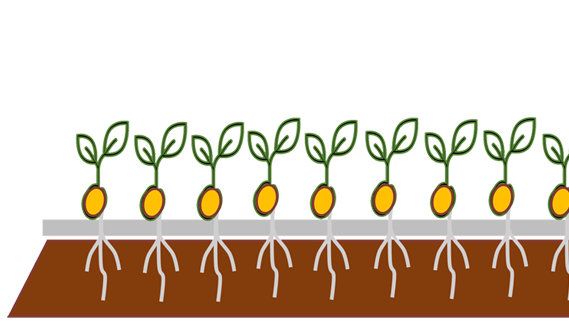

Simple and disruptive: sowing a sandwich made of two sheets of paper with the seeds in the middle. Mechanize the entire process. Develop the appropriate agronomic technique, simple, reliable and replicable on a large scale, and in different pedo-climatic conditions.

SharpCell Oy (Finland)

Company specialized in the production of paper with airlaid technology.

Ortomec srl (Italy)

Company specialized in the production of agricultural machinery for horticulture.

PRO-BE srl (Italy)

Company specialized in consulting for innovation and sustainability in agricultural supply chains.

After about ten years of experimentation dedicated to the development of paper, mechanization and agronomic techniques; noting the growing demand for effective solutions for weed control in horticulture, while respecting environment and people; considering the growing cost of manual labour, often not even available and in any case hard and uncomfortable; the three companies involved believe that the current moment is propitious for the introduction on the market of the new mulch with selective permeability paper and related automation of laying and sowing.

The benefits obtainable thanks to PAPER BE are:

Weeds control in horticultural crops without the use of pesticides

Use in both conventional and organic farming

Significant reduction of water losses

Elimination of leaves soil contamination

Containment of seed predation by insects or other animals

100% biodegradable. No introduction of plastic into the cultivated land

Other benefits:

containment of soil born diseases; increased activity of useful microorganisms; combined application with useful microorganisms and fertilizer; control of the soil temperature by being able to increase it (dark-coloured paper) or reduce it thanks to the reflection of solar radiation (white-coloured paper); positive effects for the entire supply chain in term of health of soil, products and people (One Health approach)

EIMA Technical Innovation 2022

Cost reduction and flexibility increase compared to the current solutions

These are the features of the PAPER BE technology, in a schematic description of the process:

For the success of the new mulching technique it is necessary to adopt some simple agronomic measures:

To these basic techniques will soon be added other and innovative possibilities of plant nutrition and protection using paper enriched with beneficial microorganisms and fertilizers.

In the following pictures we can see the perfect growing of roquette and baby lettuce on field

The development of this special paper required a long phase of experimentation, first in the laboratory and then in the field. The challenge was to combine all the features described above in a single product, starting with the balance of mechanical strength, stability of performances regardless of the water content and complete biodegradability.

SharpCell believed in this new use (and market) and invested heavily.

Field tests have been carried out for years with increasingly advanced materials.

Once the paper with the desired technical performance was developed and tested, we worked on the scalability of the project for the market therefore on:

Automation of paper laying and sowing operations

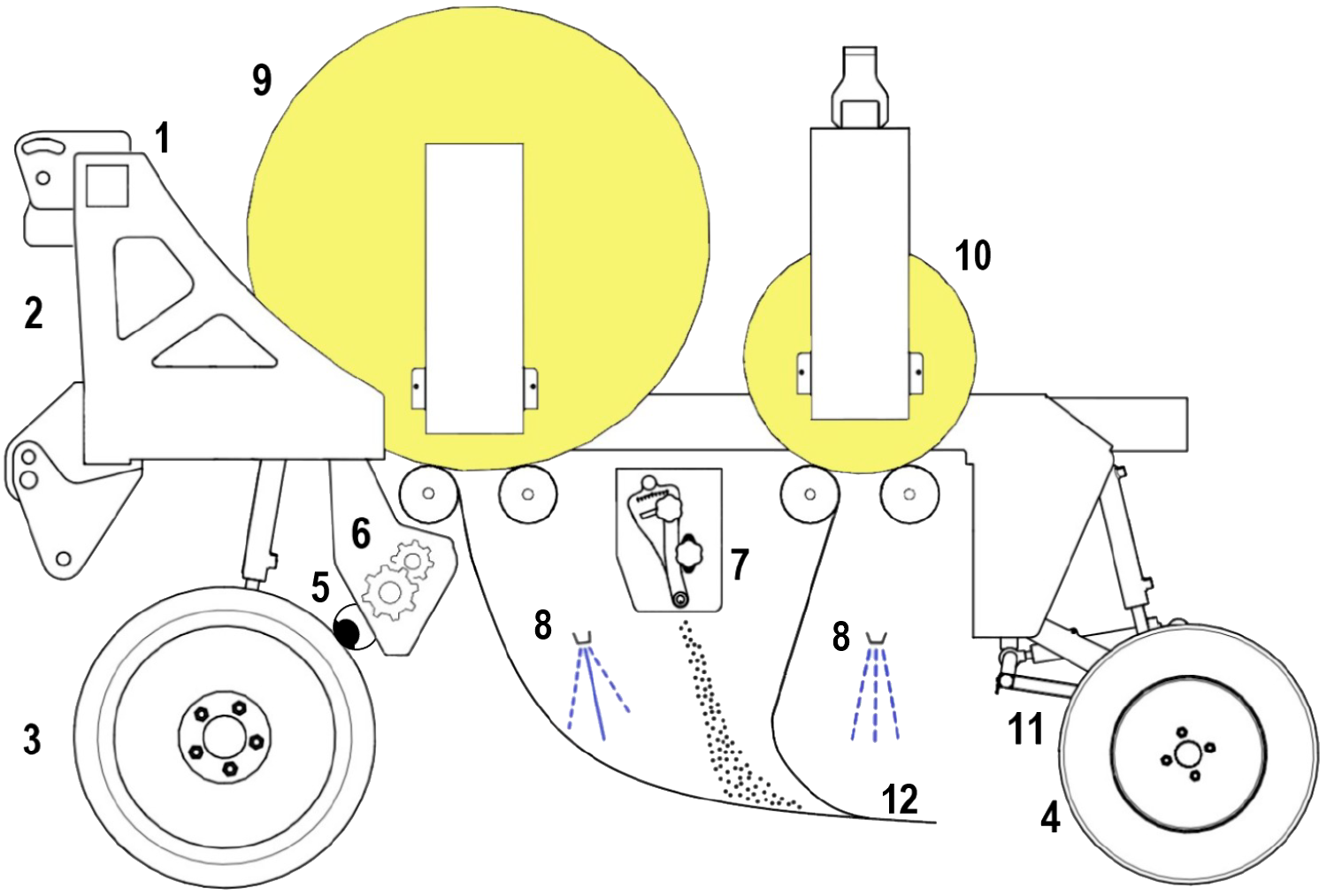

This is now possible thanks to Ortomec patented PAPER-SEED machine. It can carry out all the sowing and double mulching operations in a single step

Total costs competitive compared to alternative solutions

The machine designed and built by Ortomec allows you to achieve all this. It is the result of an open innovation project, in which companies operating in very distant technological and market fields, and very different skills, have combined and integrated their research to find an innovative solution that would otherwise be difficult to imagine. Technically it is configured as the combination of a double mulching machine with an intermediate seeder.

The paper sowing technique is not new but has always proved inapplicable: due to the lack of papers with adequate performance, in different field and crop conditions and, above all, due to the impossibility of carrying out the sowing and paper laying operations in rapid times, with the necessary flexibility and with reasonable costs, proportional to the obtainable advantages. These limits have been exceeded thanks to the new Ortomec device.

1. Open frame steel structure

2. Three-point linkage

3 and 4. Front and rear tires

5. Smooth wheel driven (with force coupling) by the front tire, which transmits and controls through a transmission with wheels and chains [6] the rotation of the reel [9 e 10] and the consequent release of the paper [12]

7. Hopper and chute for broadcast sowing, with seed distributor electrically operated and controlled by PLC

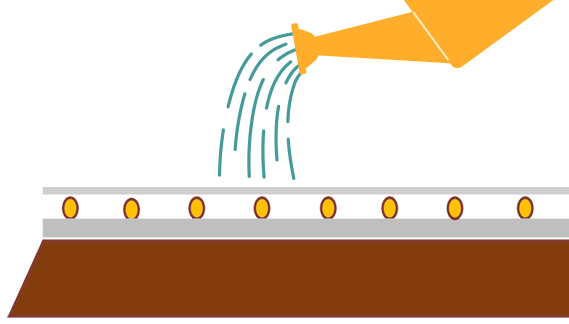

8. Wetting system

9. Reel of the growth base paper, heavy weight, used for the realization of the first mulching layer (in direct contact with the ground);

10. Reel of secondary paper, light weight, used for the realization of the second fixing and seed protection layer

11. Paper cutting and recovery system

The innovative feature of the machine lies in the possibility of posing, in once, the “sandwich” consisting of the primary and secondary layers of paper, with an intermediate seed distribution. This makes the application of the PAPER BE technique technically and economically sustainable.

More specifically, the machine can simultaneously carry out the operations of:

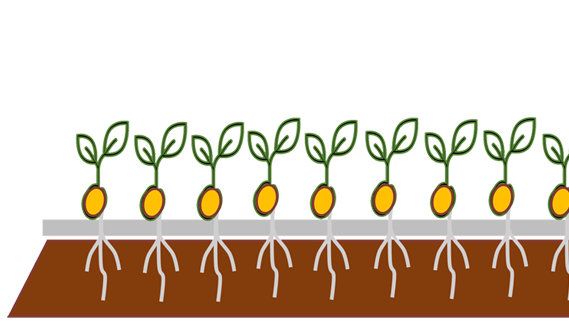

1. Placing of the primary paper layer.

The presence of the primary layer allows effective weeds control thanks to a mechanical action that blocks their growth and contains them below the paper, thus eliminating their competitiveness towards the crop. At the same time, the primary layer allows the rooting of the sprouted seeds. The mulching layer also offers a thermoregulatory action guaranteed by the ability to modulate the reflection thanks to the different color solutions available (also in combination with the secondary layer). In particular, white paper has a relatively high reflective effect which allows a reduction in the temperature of the soil and in the vicinity of the seed. Conversely, black or dark pigmented paper can act as a thermal collector, increasing soil temperature. The paper layer, characterized by a high-water absorption and diffusion capacity, favors the obtaining of a condition of high homogeneity in soil humidity. This humidity can therefore reach all the seeds deposited in a similar way, guaranteeing uniformity in germination times. The barrier action of the primary layer is also significant against water evaporation from soil. The result is water preservation between 20 and 35% depending on the microclimate

2. Distribution of seeds over the first layer of mulch.

The seeds released above the primary layer can easily emerge, without weeds competition.

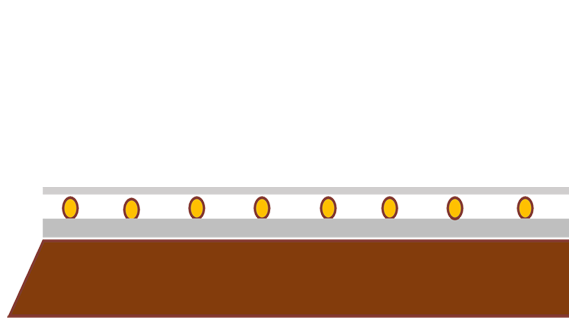

3. Posing of a secondary mulching layer

The secondary mulching layer is spread and adhered to the primary by spraying water. In this way the “sandwich” is made, consisting of two layers of biodegradable paper with the seed interposed. The primary layer constitutes a real mulch, the second allows a mechanical stabilization of the seed and degrades very quickly so as not to hinder the seedlings during the first stages of growth.

4. Automation of headland operations.

Starting and ending laying operations are simplified thanks to the automatic paper cutting and subsequent resumption.

To receive more information or request a quote, fill out the form below.

You will receive a prompt reply.